New polymer modified materials (environment friendly flame retardant masterbatch, compatibilizer, PP/PE modified material, glass fiber modified material, talc filled masterbatch, barium sulfate filled masterbatch) , widely used in home appliances, automobiles, energy, building materials, electronics, aerospace and so on. used in: pipe, profile, film products, bag products and injection molding products

The environmentally friendly flame retardant masterbatch is a highly efficient flame retardant developed by our company's scientific research team through long-term scientific experiments. It has the characteristics of small addition, good flame retardant effect, good

compatibility with resin, and environmental protection and non-toxic.

Applicable industry: PP products flame retardant

Reference addition amount: 8-12% level: V0

Compatibilizers make the materials have high polarity and reactivity by introducing strong polar reactive groups, and can be used for flame retardant, reinforcement, toughening, filling, bonding, metal bonding, plastic modification, toughening resistance Impact, plastic alloy compatibility, engineering plastic modification, PA/PE toughened bonding layer, PA and other toughness, ABS/PC, PBT/PC and other alloy compatibilizers. Can greatly improve the compatibility of composite materials and the dispersion of fillers, improve product performance.

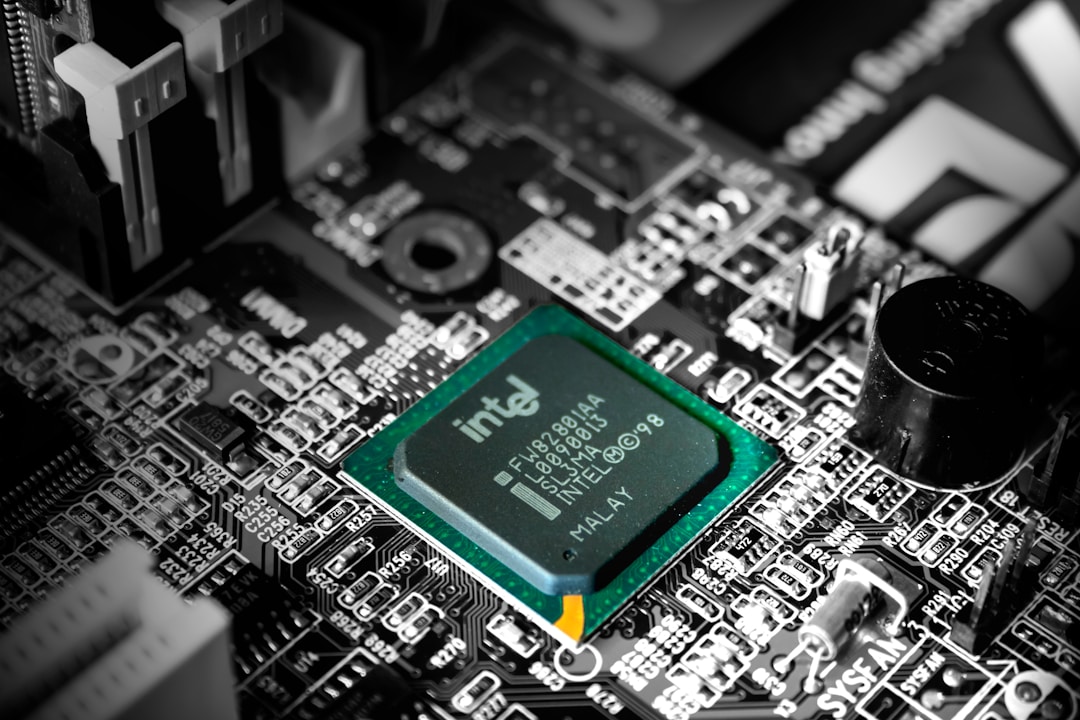

Reinforced and toughened modified materials refer to the processing of filling and reinforcement based on general plastics and engineering plastics, which improves flame retardancy, strength, impact resistance and toughness. Due to the characteristics of good electrical properties, high temperature resistance and dimensional stability, flame retardancy, radioactivity resistance, chemical resistance and mechanical properties are also relatively good, which can increase the strength and toughness of plastics at low temperatures. Widely used in cutting-edge technology fields such as electronic appliances, automobiles, instrument and meter, home appliances, aviation, paint industry, aerospace, etc.

Graphene is a single atomic layer two-dimensional sheet structure formed by the hybridization of carbon atoms through SP2, this special structure has a very good thermal conductivity, 10 times that of copper. Graphene is one of the strongest materials known

Application area

Car

Chip

Home appliances

High-speed rail

Energy

Aerospace

Building materials

E-mail:

AmyMeng@aodanewmaterials.com

WhatsApp:

+86-18832916789

Address:

Southbound 100 meters of North International Convention and Exhibition Center , Donghuan Road, Pingxiang County, Xingtai City,Hebei Province

Newpolymer modified material

Classification

Tag: